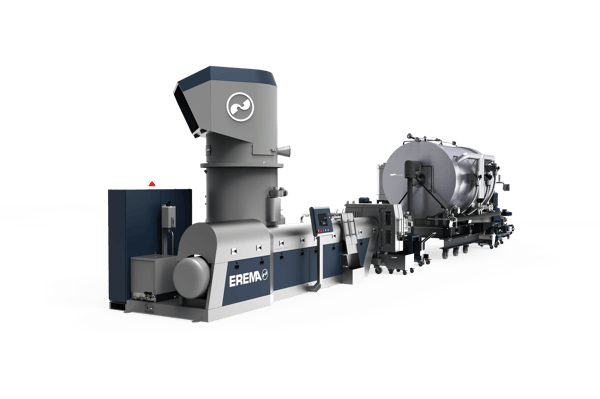

The latest addition to our lineup is the INTAREMA® FibrePro:IV, a cutting-edge solution designed specifically for PET fiber-to-fiber recycling. This groundbreaking machine will be launched at ITMA in Milan from June 8 to 14, showcasing its exceptional capabilities.

The INTAREMA® FibrePro:IV sets itself apart with its gentle material preparation and efficient removal of spinning oils, enabling the production of rPET that can be reused up to 100 percent in the creation of fine textile fibers.

Wolfgang Hermann, Business Development Manager at EREMA Group GmbH, explains the motivation behind this development: "While PET recycling machines have been used in fiber recycling, a new technological solution was required to reuse these recycled fibers in higher-quality applications." PET stands as a crucial material in the production of synthetic fibers, with approximately two-thirds of PET being allocated to PET fiber production for the textile industry.

This emphasizes the significance of high-quality recycling solutions to foster a circular economy. By combining the well-established INTAREMA® technology with a new IV optimizer, EREMA achieves the processing of heavily contaminated shredded PET fiber materials, resulting in the production of fine fibers from recycled pellets. The INTAREMA® FibrePro:IV, an exceptional addition to EREMA's machine portfolio, boasts an extended residence time for the PET melt. This pivotal feature ensures the removal of spinning oils and other additives used to enhance fiber handling during manufacturing more efficiently than conventional PET recycling processes.

The PET melt undergoes polycondensation in the new IV optimizer, under high vacuum, increasing its intrinsic viscosity (IV) to the precise level necessary for fiber production. "Through this recycling process, including filtration, we achieve remarkable output quality, enabling the production of ultra-fine fibers as low as 2 dtex using 100 percent rPET content," highlights Markus Huber-Lindinger, Managing Director at EREMA. Consequently, waste PET fiber from production processes can be transformed into rPET filament fiber, carpet yarn, and staple fiber.

While the current focus of the fiber and textiles application centers on PET fiber recycling, EREMA remains committed to advancing the recycling of mixed fiber materials from traditional textile recycling collections in the next phase of their project. To expedite development efforts, the EREMA Group has established its dedicated fiber test center, where a team of experts collaborates on recycling solutions for fiber-to-fiber applications. The center houses a fully equipped and adaptable industrial-scale recycling plant, along with the necessary peripheral technology, facilitating customer trials and experimentation.