Recycling odor, especially in post-consumer recycling, is an issue both during the recycling process and after, when the pellets themselves can carry undesirable odors. Such odors are usually caused by organic materials, including cellulose and food contamination. When present these organic materials can significantly reduce the value of the recycled plastic as surely as can deficiencies in mechanical properties or color. Nobody wants smelly pellets. To make circular economy in plastics a reality we need quality pellets that can make new parts.

The human nose can detect some substances when their concentration is only a few milligrams per 1000 tons which is less than a drop in an Olympic swimming pool.

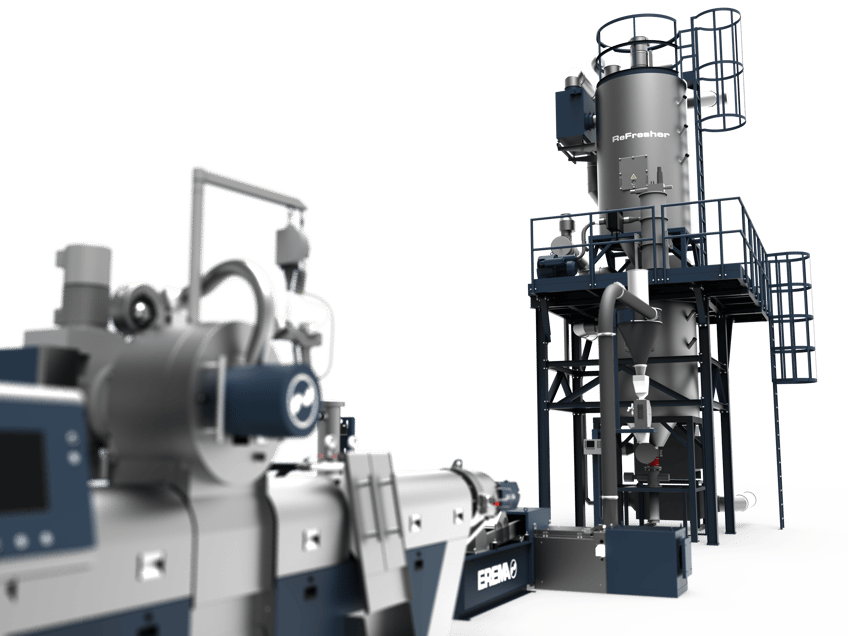

EREMA’s Recycling system, in combination with ReFresher technology, minimizes odor, depending on input material and processing, to what can be essentially odorless.

Specifically, the ReFresher unit, again depending on input material and operation, can reduce odor to less than 0.1 parts per million (Limonene tracer content, gas chromatograph). The ReFresher unit, efficiently discharges volatile, smelly substances with hot air as a carrier gas.

If you want pellets that don’t smell and to produce high value products—talk to us or download our related technical article.