A new study titled “Cradle-To-Resin Life Cycle Analysis (LCA) of Polyethylene Terephthalate (PET) Resin.” has been released by The National Association for PET Container Resources (NAPCOR). Manufacturers can now calculate the impact of moving to Polyethylene Terephthalate Recycling with the resulting analysis and calculator.

The Polyethylene Terephthalate recycling study collected data to compare the environmental impacts of manufacturing virgin Polyethylene Terephthalate vs Polyethylene Terephthalate recycling. Included in the study were the impacts of energy usage, the generation of solid waste, and environmental emissions of both virgin Polyethylene Terephthalate production and collectin, sorting, and processing Polyethylene Terephthalate recyclate back to a clean, usable resin.

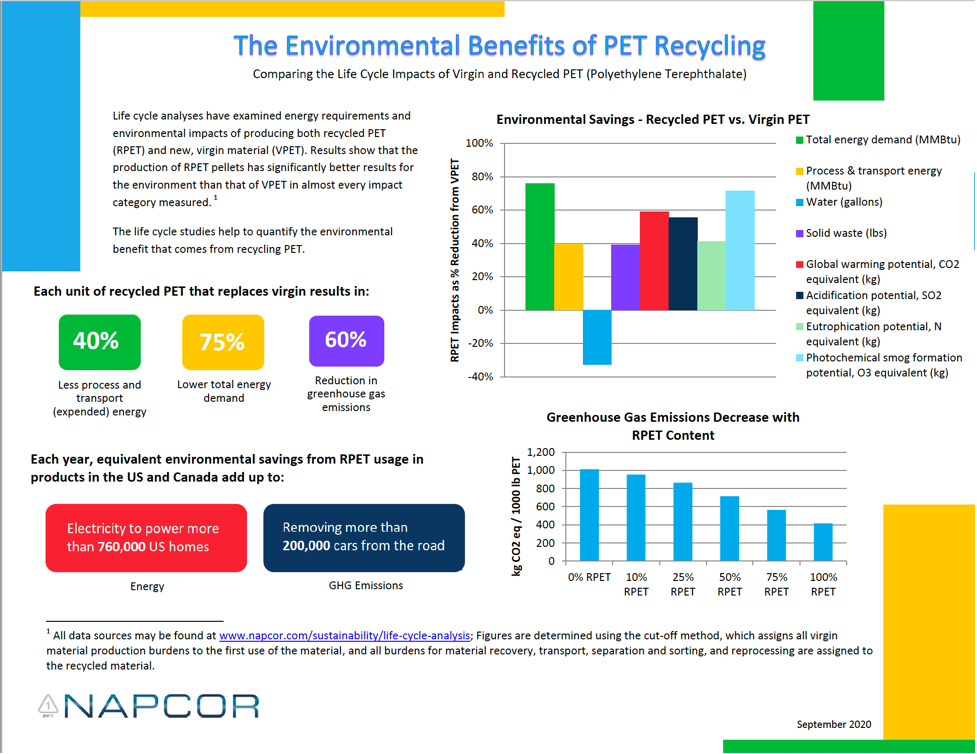

A summary infographic of the impact of Polyethylene Terephthalate recycling is shown below.

The Polyethylene Terephthalate Recycling Study Highlights:

- Polyethylene Terephthalate recycling reduces greenhouse gas emissions by 60%.

- Polyethylene Terephthalate recycling reduces energy demand by 75%

- Polyethylene Terephthalate recycling reduces processing and transportation energy usage by 40%.

The study also generated a calculator that manufacturers can use to model their own environmental impact when they move toward Polyethylene Terephthalate recycling.

The calculator lets manufacturers create an environmental report based upon the study’s data for the impact of moving a specified weight and percentage of their production process towards recycled Polyethylene Terephthalate.

You can access the calculator and model your own company’s environmental impact here.

The report also details the economic impact of Polyethylene Terephthalate Recycling including the impact on economic growth and job creation.

Learn more about the details of the NAPCOR study here.