A key technology building block for plastic recycling systems are the so-called melt filters. Essential for the quality of the output material, melt filtration system remove non-plastic particles from the recycled plastic such as paper, wood, sand, glass or aluminum pieces. To achieve a high-quality pellet at the end of the recycling process, the right filtration technology should be chosen based on the input materials.

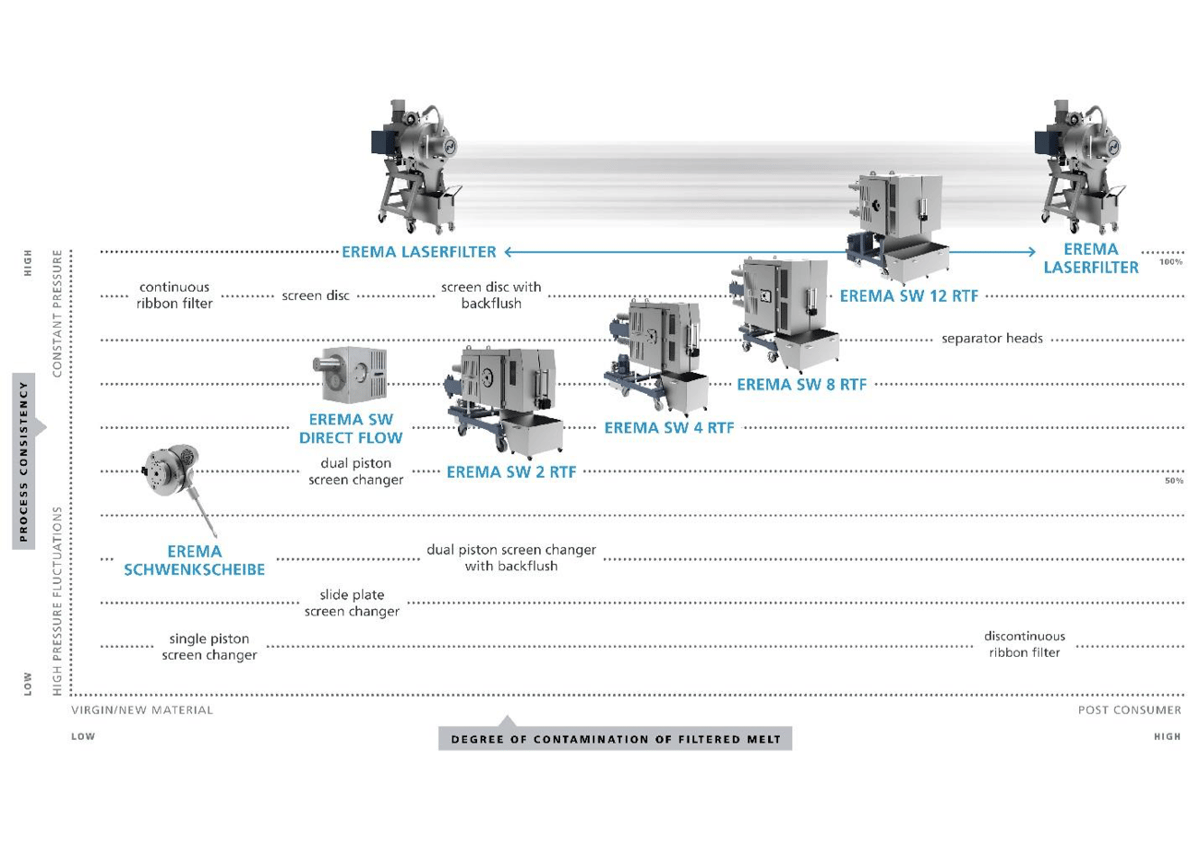

EREMA helps their customers choosing the right system for the application. We principally differentiate between back flush filtration (a cyclical process) and continuous filtration. The SW RTF, a cyclical filter system, provides excellent filtration options down to mesh sizes as small as 32 microns for very fine filtration. The Laser Filter (the filtration discs holes are burned with a laser), a continuous filter system, can go as low as 70 microns but can handle significant higher amounts of contamination.

Key performance criteria that should be taken into consideration:

Automation

A melt filter system should be fully integrated into the extruder system. A good melt filter adjusts automatically to the degree of contamination that is coming from the input material. Rather than relying on operators to be involved in adjusting the system, a state of the art filter adjusts automatically. Filter systems should also not require a shut-down of the extruder but allow for filter changes while the extruder keeps working. A high degree of automation also reduces labor costs and training requirements.

Simplicity

Simplicity and Robustness is an important criterion, especially for post-consumer recycling materials. The melt should flow through the system without dead spots (material hang ups), large surface areas prevent pressure spikes, access to the filters should be simple and fast for operators, an intuitive HMI helps the operator to interact with the system. Any wear components in the system should be easily accessible to minimize down time and eliminate complex training requirements for operators.

Contaminant Removal

Analyzing what kind of contaminants are in your material stream and optimizing the filtration solution accordingly is key to success. How much contaminants are in the plastic stream leads to a decision if continuous or cyclical filtration is required. The type of contaminants and to what degree they need to be filtered out will drive decisions about processing (pressure, temperatures) and filtration fineness.

Maintenance Cost

Any buyer of filtration systems should not just consider initial capital investment, but equally important the on-going maintenance and consumables cost. Based on the input materials and contamination levels these costs can be estimated prior to purchasing the equipment. Typically filters and in the case of continuous filter systems, knives are the key consumables. Some systems, like the EREMA Laser Filter allows the cleaning and re-use of the filter discs.

Choosing the right System:

Find more details at: www.powerfil.com

Find more details at: www.powerfil.comIf you want to learn more about plastic melt filtration options, visit us at Plastics Recycling Show and Conference in Washington DC – March 11-13.