As outlined in our last blog post, PET recycling is facing challenges technically and on the collection side. Erema constantly improves its systems to meet the technical challenges of PET Recycling. The new VACUNITE® bottle-to-bottle process is the first PET recycling system that meets today’s stricter quality criteria for recycled plastics in food-contact applications and satisfies the packaging industry’s demand for greater recycle content.

The VACUNITE® process is based on the combination of VACUREMA® technology - which has been proven over the past 20 years and has been further developed especially for this application. It is combined - together with the newly patented vacuum-assisted Solid State Polycondensation (SSP) system, which was specially developed by Polymetrix for EREMA. The process brings together two established technologies in which all thermal process steps occur in a nitrogen and/or vacuum atmosphere.

Among key advantages of the VACUREMA® technology is that it can handle dust and fine particles more effectively than competitive technologies thanks to the energy input by mechanical friction. This process step is particularly suited for applications in which a high content of PET fines is present. This eliminates the need for for costly and time-consuming dedusting.

Another special feature of VACUNITE® technology is that the sluice and reactor are purged with high-purity nitrogen (99.99 % N2). In ambient air, the oxygen content is about 21%, while at 10 mbar absolute it is only around 200 ppm. Nitrogen purging significantly reduces the residual oxygen content to < 3ppm (0.0003 %), to further reduce the yellow coloration.

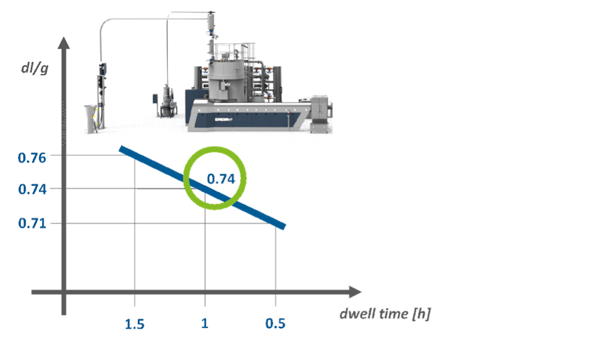

A key benefit is the patented positioning of reactor and extruder which ensures gentle melting of the PET flakes. Gases given off in the process are extracted backwards via the reactor. Due to the high temperature inside the reactor, the extruder introduces less melt energy into the material, so the screw can be up to 40% shorter than in comparable recycling systems. As a result, no additional degassing is required in the middle of the extruder and the dwell time of the material in the extruder is considerably shorter. The efficient pre-drying in the reactor and the short screw length of screw keeps the IV loss of the PET material to a minimum.

The process uses an EREMA backflush filter with about 40µm filtration fineness. The key feature of the EREMA filter is the large active filtration area, which lowers the pressure in the extruder to prevent solid contaminants being forced through the filtration medium. The melt filter operates semi-automatically, i.e. backflush sequences are triggered depending on the differential pressures and the screen is backflushed with clean material (1% material loss).

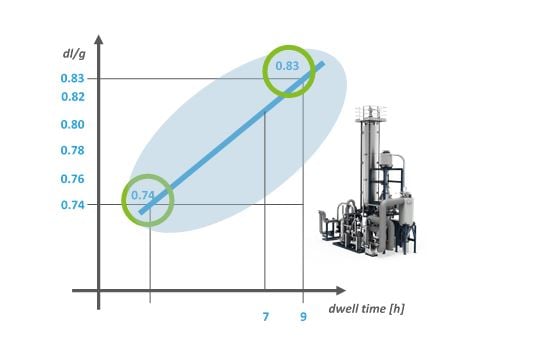

The nitrogen is injected into the SSP by means of a contraflow process. On its way to the top, it absorbs contaminants, glycol, and water from the pellets, which are the by-products of the IV increasing process. In the subsequent water ring pump system, the nitrogen is purified again so that it can be returned to the upstream process steps. In addition, the viscosity in the SSP is raised again to values suitable for preform production.

The special configuration of this system and the temperature control of the VACUNITE process enables high crystallization rates (>40%, determined using the density method) without the need for an additional post-crystallization process. The VACUNITE® process requires 40% fewer components and uses 36% less energy than comparable systems. The energy consumption of VACUNITE® for the entire production process from flake to final pellets is just 0.35 kWh per kg.

The VACUNITE process is an innovative new technology that sets new standards at all levels, from technical performance to recyclate quality.

To learn more about Advanced PET Recycling Technology visit our guide here.